Bambu Lab - PVA - Clear (66400)

Bambu PVA

Bambu PVA is a water-dissolvable support material. It provides reliable support for complex designs and overhangs, which can be easily dissolved in water after printing. Compatible with various filaments, it simplifies post-processing and reduces the risk of damaging the printed object during support removal.

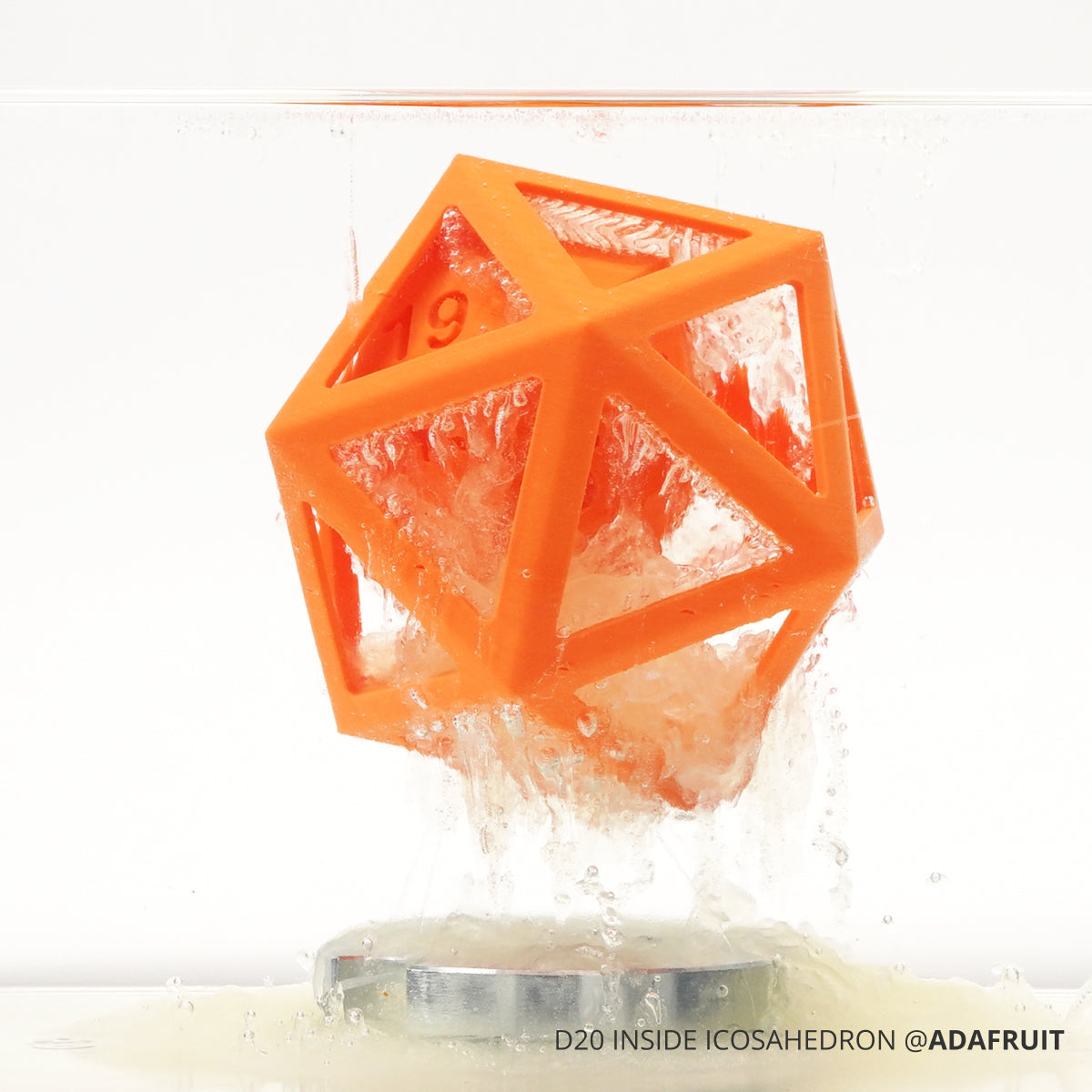

Soak and Dissolve for Supporting Intricate Details

Bambu PVA possesses the ability to dissolve in water, penetrating deep into the intricacies to provide support where regular supports fall short. With Bambu PVA you can design and print models that were previously impossible.

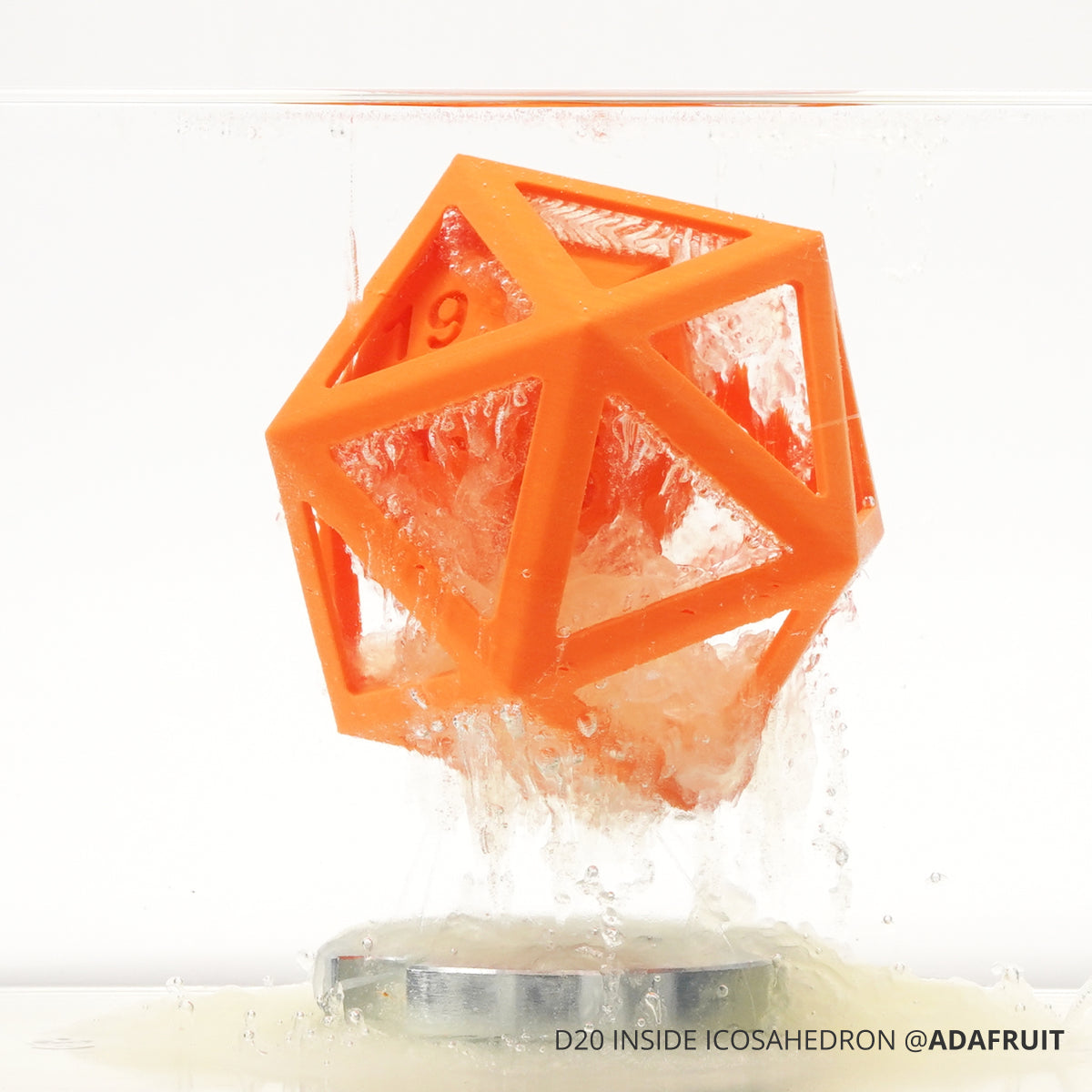

Seamless Support Interface Surface

Water-soluble support material can accommodate zero top interface spacing, guaranteeing a seamless bond with the print surface, resulting in precise and smooth support contact surfaces for your prints.

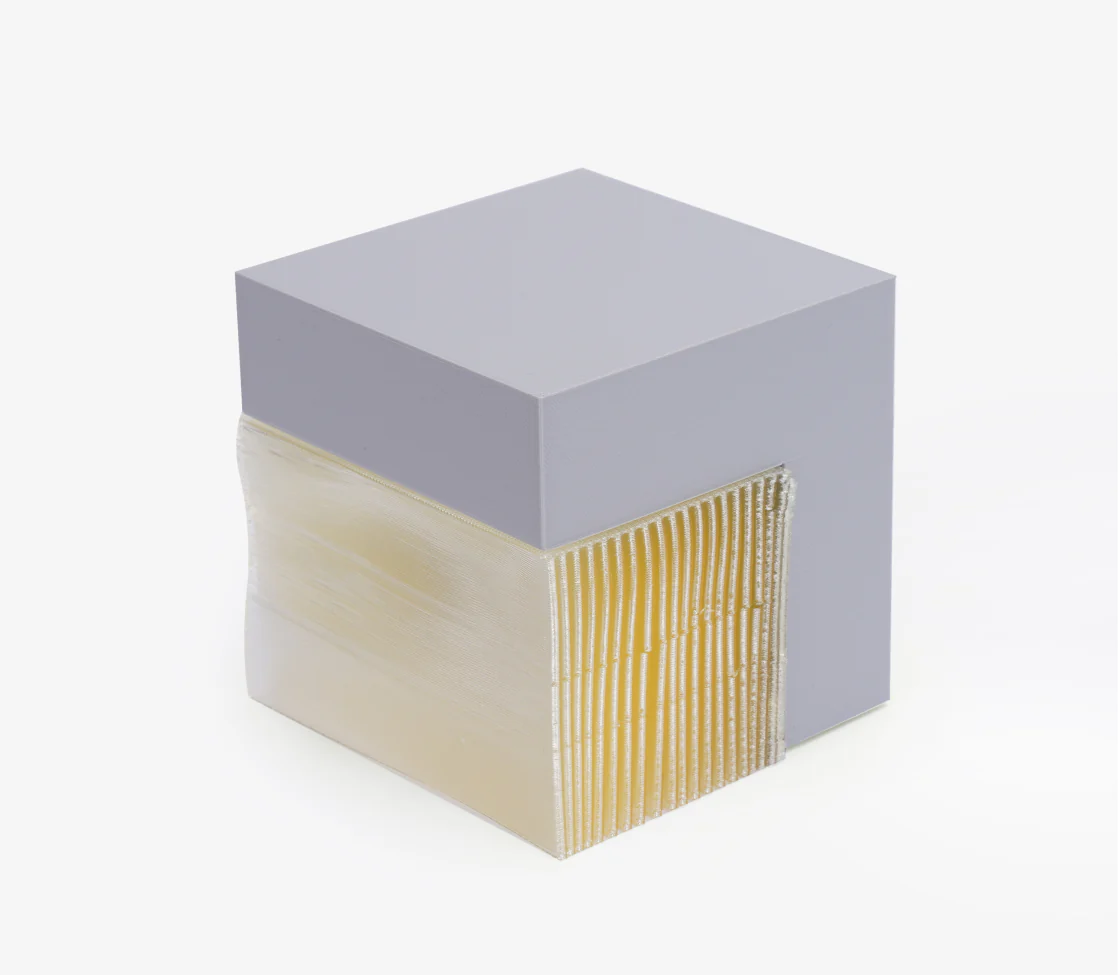

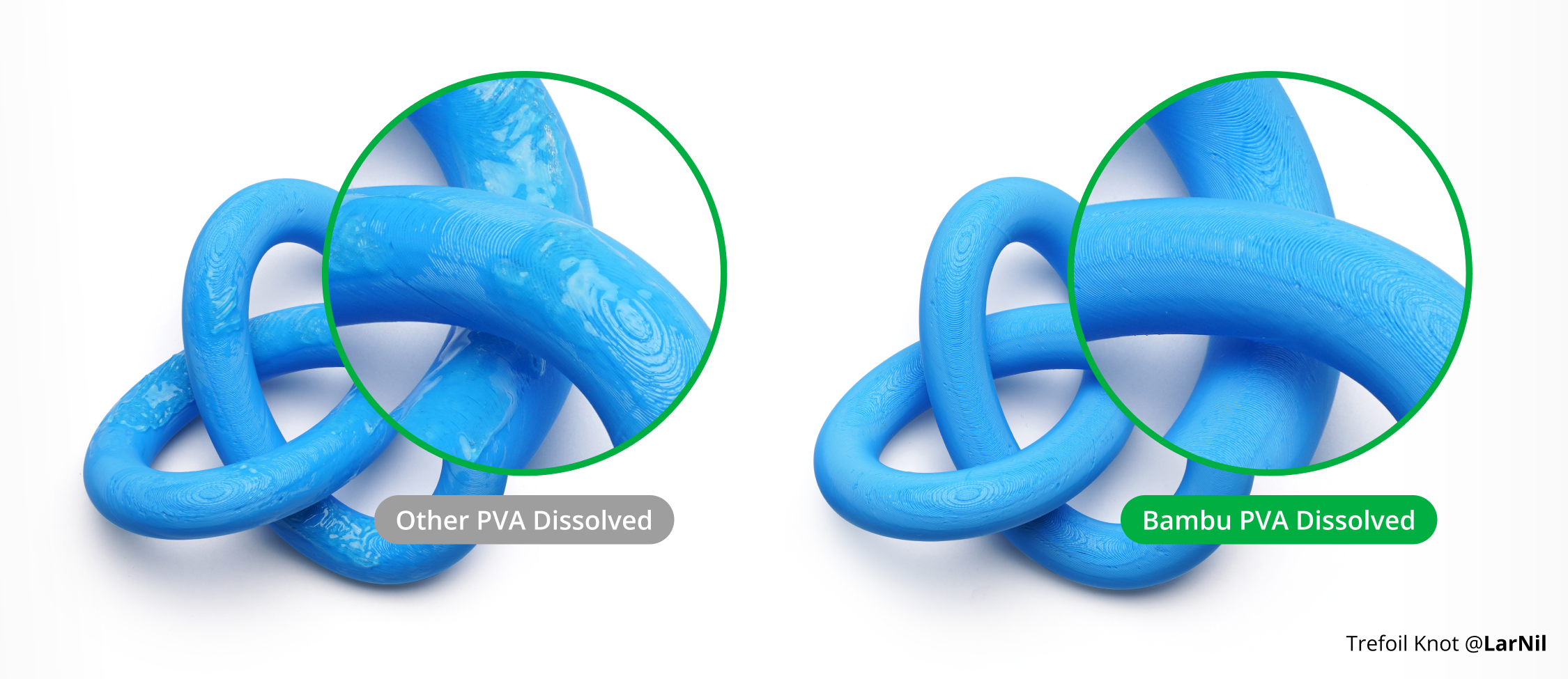

Thorough and Clean Dissolution

Bambu PVA utilizes a high-quality formula that dissolves easily and thoroughly in water, effortlessly removing support material and eliminating the hassle of manual cleaning.

Support Filament Comparision

| PVA | Support for PLA | Support for PA/PET | |

| Compatibility | PLA, PETG, PLA-CF/GF, PETG-CF/GF | PLA, PLA-CF/GF | PA, PA-CF/GF, PA6-CF/GF PAHT-CF/GF, PET-CF/GF |

| Nozzle Compatibility | Hotend with Hardened Steel Nozzle 0.4 mm / 0.6 mm / 0.8 mm Hotend with Stainless Steel Nozzle 0.4 mm |

All Size / Material | Hotend with Hardened Steel 0.4mm / 0.6mm (recommended) / 0.8 mm |

| Solubility | Water-dissolvable | Water-insoluble | |

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate | / |

| Hotend | Hotend with Hardened Steel Nozzle 0.4 mm / 0.6 mm / 0.8 mm Hotend with Stainless Steel Nozzle 0.4 mm |

Hotend with Stainless Steel Nozzle 0.2 mm |

| Glue | Bambu Liquid Glue / Glue Stick | / |

PVA Hex Code Table

| Color | Hex Code | Display | |

| Clear | #F0F1A8 | ||

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 80 °C, 12 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 220 - 250 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 200 mm/s |

| Physical Properties | |

| Density | 1.27 g/cm³ |

| Vicat Softening Temperature | N / A |

| Heat Deflection Temperature | N / A |

| Melting Temperature | 202 °C |

| Melt Index | 7.2 ± 1.1 g/10 min |

| Mechanical Properties | |

| Tensile Strength | N / A |

| Breaking Elongation Rate | N / A |

| Bending Modulus | N / A |

| Bending Strength | N / A |

| Impact Strength | N / A |

Printing Tips

• Drying conditions: 80°C for 12 hours. For optimal printing performance, it must be thoroughly dried before use and after storage. For more details please refer to: Filament drying instructions on WIKI.

• Please carefully read PVA Printing Guide before starting the printing process.

• PVA is suitable for use with AMS and AMS lite in a dry state. If the filament becomes soft or sticky due to moisture, it must be dried again before use to prevent issues such as feeding failure, nozzle clogging, and low print quality.

• PVA may darken in color after extended storage or multiple drying cycles, but it won't affect its printing performance or support capabilities.

• Recommend to use normal support instead of tree support. Tree support is more likely to collapse during printing.

• Use warm water to speed up the dissolving process. But if supporting PLA, the maximum water soaking temperature should not exceed 50°C to prevent deformation of the main model.

• Waiting for complete dissolution is not necessary when soaking and dissolving PVA support. You can manually remove the partially dissolved PVA support to reduce the waiting time.

• When dissolving supports in water, some parts of the main model may leak in water. To mitigate this risk, please refer to:Reduce the risk of prints leakage guide on WIKI.

• Depending on the use case, Bambu PVA can also be used solely for printing the support interface to minimize material waste and printing time.

What's in the Box

Filament with Spool*1

Package*1