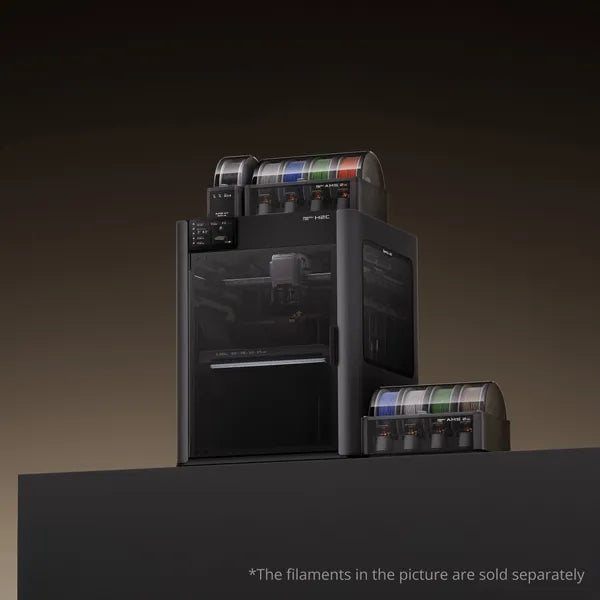

Bambu Lab H2C

Product Features

- Hotend Change Multi-material Printing

- Minimal Purge Waste Multi-Color Printing

- Precise & Fast Inductive Nozzle Heating

- Close-loop Servo Extruder

- Full Filament Path AI Error Detection

- 350°C Nozzles & 65°C Active Heated Chamber

- Optional 10W/40W Laser and Cutting Module

- 330*320*325 mm³ Build Volume

Revolutionize How You Print Your Projects

Vortek Hotend Change System

In traditional single-nozzle multi-material printing, purging is needed to clear leftover material between filament changes.Vortek changes that with an intelligent hotend-swapping system that replaces the entire hotend — delivering faster, cleaner prints with minimal waste.

The Vortek system works seamlessly with our highly reliable AMS (Automatic Material System), making the entire filament change process fully automatic — no need to manually load each filament into the toolhead.

Always Delivering the Most Efficient Combination

The Vortek system can store filament information in the hotend’s memory, ensuring the correct filament is matched to each hotend. If you are printing with more than seven filament types, the system can calculate the optimal combination to minimize purge waste.

Why Vortek?

Because only the hotend is swapped, the system can house up to six replaceable hotends without significantly reducing the build volume.That means more materials, more colors, and more possibilities — all in one print.

8-Second Induction Heating

Our industry-leading induction heating technology brings the nozzle to temperature in 8-sec, significantly reducing the preheating time for each material swap compared to traditional methods.

Contactless Design For Reliability

Our high standards for reliability led us to move away from contact-based metal pins, which are prone to oxidation and unstable connections.We developed a contactless solution that ensures a stable, high-frequency connection — the foundation for precise temperature control and intelligent hotend sync.

Colors Are No Longer Limited By How Many Toolheads You Have

Unlike traditional toolchanger printers that limit color count by the number of toolheads, the H2C supports up to 24 materials in a single print through parallel-connected AMS units. Its intelligent algorithm optimizes filament-to-hotend allocation to minimize purge waste while delivering outstanding multi-color and multi-material results.

Enclosed for High-Performance Printing

With its seamless enclosure and adaptive airflow system, the H2C maintains a stable chamber temperature for high-performance materials and filters the air to keep your workspace clean and safe.

Fully Automatic Nozzle Offset Calibration

Our inductive nozzle offset calibration is fully automated — no manual steps, no calibration plates, no extra setup. In just a few minutes, the H2C precisely calibrates nozzle offset to within 25 microns.*

Dedicated Hotends for Specific Filaments

The H2C's Vortek system lets you dedicate one of its six interchangeable hotends to specific filaments — a game-changer for valuable engineering materials.This ensures superior consistency and reliability across prints. Each hotend can even automatically store filament information, so the next time you load that material, it's instantly matched to the correct hotend.

Not A Toy, A Serious Production Powerhouse

50 µm Ultra-Fine Motion Accuracy*

The H2C's 65 °C actively heated chamber & 350°C Nozzles minimizes warping and deformation while enhancing layer adhesion for high-performance, high-temperature filaments.

Comprehensive Print Monitoring

The H2C is equipped with an array of 59 sensors* and a quad-camera computer vision system, all orchestrated by our proprietary neural algorithm. This system delivers intelligent, real-time diagnostics that can detect even the most subtle print anomalies as they happen. You don't have to be an expert to solve problems—your printer does the job for you.

The H2C features an AI-backed camera system. This intelligent monitoring system continuously tracks extrusion patterns, immediately detecting material accumulation, filament deviations, and extrusion failures. Also runs a pre-flight scan to ensure a safe start.

Safety, Checked!

Best-In-Class Air Filtration

The H2C's three-stage filtration system is essential for printing with engineering filaments. This powerful combination of a G3 pre-filter, an H12 HEPA filter, and a coconut shell activated carbon filter effectively minimizes the odors and harmful particulates often released by engineering materials.

The H2C's chamber is constructed entirely with flame-retardant material, providing robust, passive fire safety protection across the entire enclosure.

The H2C offers convenient cloud connectivity for remote control from any device. For security-sensitive applications, it also provides full offline functionality, ensuring complete physical isolation. Users can operate the printer, send files, and update firmware without an internet connection. For advanced users, Developer Mode enables MQTT port access for integrating third-party components and software.*

What's in the box

FAQ

1. What hotends are included in the H2C Combo?

2. If I want full hotend-swap capability, what additional hotends do I need? How should the AMS be connected?

Future Setup (2026): A Filament Track Switch Module will be released, allowing full 7-hotend support with only 2 AMS units, enabling free filament switching between left & right filament paths.