Bambu Lab P2S 3D Printer

Note: The standalone P2S (without AMS) does not include a filament buffer.

Please be aware that the absence of the filament buffer will affect the accuracy of filament tangle detection feature.

Product Features

- 5-Inch Touch Screen

- AI Failure Detection

- Auto Flow Dynamics Calibration

- Multi-Color Printing

- Cold-Air Cooling

- Active Venting Filament Drying

- 256*256*256 mm³ Print Volume

* Cybersecurity compliant with EU RED Article 3.3(d)(e). Learn more.

Highlights

| 5-inch Refreshed Touchscreen |

|

| Cold-Air Cooling | |

| Engineering Filaments Ready | |

| Quick-Swap Nozzle | |

| PMSM Servo Extruder | |

| Silky-Smooth Liveview | |

| Auto Flow Dynamics Calibration | |

| Active Venting Filament Drying | |

|

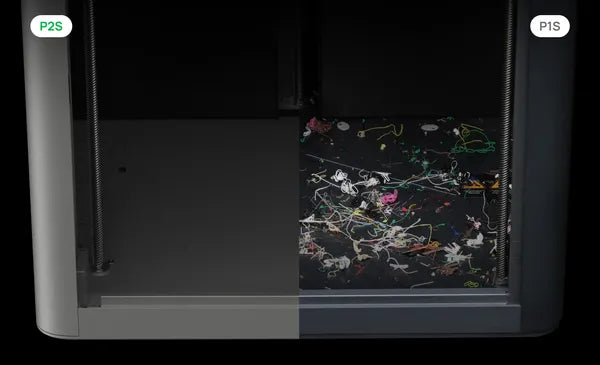

AI Error Detection

|

| |

On

|

Off

|

30-Second Nozzle Swap.

Perfection, Detail by Detail.

The P2S features numerous refinements that enhance the user experience. While these incremental improvements may not be immediately apparent, they embody the level of perfection Bambu Lab constantly pursues.

Effortlessly switch between your AMS and external filament spools for maximum flexibility.

P2S Specs

Bambu Lab P2S |

|

AMS 2 Pro

|

|

Filament Buffer

|

|

Buildplate |

|

Accessory Box |

|

Spool Holder |

Frequently Asked Questions

-

What materials are the P2S pre-installed extruder gears and nozzle made of?

- Hardened steel.

- Does the P2S require an external power supply to use the dry filament function when connected to the AMS 2 Pro?

- You can use the AMS 2 Pro's drying function while the entire machine is in standby, though printing-related functions will be paused during drying. If you need to dry filament while printing, you'll need to purchase a Bambu Lab official power adapter to power the AMS 2 Pro. - Are the P2S buildplate and the XPA series buildplates compatible?

- The P2S buildplate's recognition function has been optimized. Older build plates do not support the type recognition feature, but their external dimensions are consistent, so they can still be used for printing. - The left side of the P2S has some mounting points. Does it support installing an auxiliary part cooling fan?

- You can purchase an official auxiliary cooling fan for upgrading. - Can the P2S use the nozzle of A1 and H2D?

- It's compatible with H2D nozzles but not with A1 nozzles. - How many AMS units can the P2S connect to at most?

- It supports connecting to 4 AMS 2 Pro units and 4 AMS HT units, totaling 8 AMS units with 20 slots. This means it supports up to 20-color printing. - Does the P2S support chamber temperature control, and how is the temperature controlled?

- The P2S does not have an active chamber heating function, but it can regulate chamber temperature through its enclosed chamber and automatic switching flap between internal and external circulation. - Why did the P2S stop using carbon rods?

- To allow for easier maintenance. Dirt residual is much simpler to clean off the surface of a smooth rod. - Will the P1S stop being sold?

- There are no plans for that at the moment. Please stay tuned for official announcements.

USA Orders

- Orders to the US are subject to all US tariffs for the country of manufacture of the given product (Bambu Lab -> China). This is collected by the given freight company. CAZ 3D does not collect any duties or tariffs up front. If delivery is refused and the product is sent back to us, we will subtract shipping costs to and from the delivery location on top of a USA specific restocking fee of 25% due to additional clearance requirements.