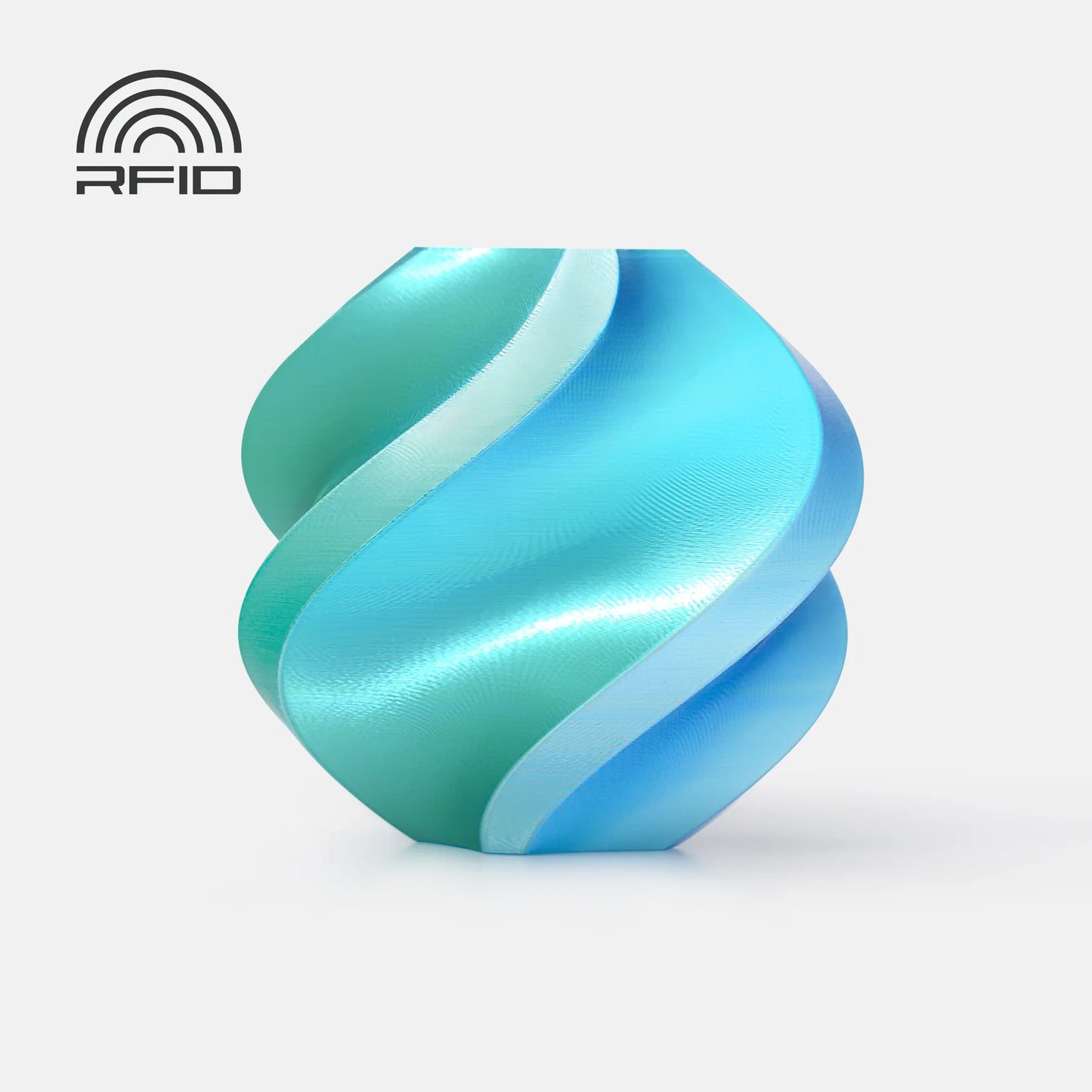

PLA Silk Multi-Color

Bambu PLA Silk Multi-Color

Bambu PLA Silk Multi-Color is available in two distinct styles: PLA Silk Dual Color and PLA Silk Gradient.

PLA Silk Dual Color is crafted by blending two vibrant silk tones into one filament strand. The color of your prints can be changed by rotating the filament to different orientations. PLA Silk Gradient includes 2 to 4 smooth, flowing color transitions per spool, creating elegant, multitone effects in a single print. Both variants offer a silky texture and high-gloss finish, perfect for making your models visually striking and professional.

PLA Silk Dual Color: Captivating Silk Appearance with Dynamic Effects

Experience stunning dual-color effects with Bambu PLA Silk Dual Color. Each filament combines two distinct hues, seamlessly merged into one strand. As you rotate the printed object, shifting color perspectives reveal vibrant, ever-changing patterns. Ideal for decorative models, figurines, and display pieces.

PLA Silk Gradient: Smooth, Stunning Color Transitions in One Spool

Bambu PLA Silk Gradient offers 2 to 4 graceful color shifts within a single spool, producing elegant, eye-catching prints. Whether you're creating vases, sculptures, or decorative designs, this filament brings depth and brilliance through its flowing, silk-like gradients.

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate, 3D Effect Plate | / |

| Hotend | Hotend with Hardened Steel Nozzle 0.4 mm Hotend with Stainless Steel Nozzle 0.2 mm / 0.4 mm |

Hotend with Hardened Steel Nozzle 0.6 mm / 0.8 mm |

| Glue | Liquid Glue / Glue Stick | / |

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

Downloads

Printing Tips

• Drying conditions: 55℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI.

• It's strongly recommended to reduce the outer wall speed to 40 mm/s to optimize print quality.

• When printing with PLA Silk Dual Color filament, there is a small chance of filament rotation, potentially causing uneven color transitions. The A-series printers have a higher risk due to their special structure, so use of this filament with A-series printers is not recommended.

Gradient Effects

• The gradient effect depends on the amount of filament used, which can be influenced by adjusting sparse infill density, print quantity, or the filament spool starting point.

• Each color segment in Bambu PLA Silk Gradient spans approximately 20m (65g+).

• Using 40m (125g+) of filament guarantees at least one two-color transition.

• For four-color transitions (e.g., Bambu PLA Gradient – Dawn Radiance), using 80m (250g+) or more ensures the full effect.

What's in the Box

* The color and texture of the filament are subject to the physical product. Images are for reference only.