Bambu Lab PLA-CF

Bambu PLA-CF

Bambu PLA-CF is carbon fiber reinforced PLA with improved stiffness and strength. PLA-CF is easy to print and beginner-friendly like regular PLA. It is AMS compatible with low clogging risk at high-speed printing. The prints are in matte finish with almost invisible layer lines, which make it suitable for printing general engineering parts or models requiring a better appearance, like bike frames, brackets and toys.

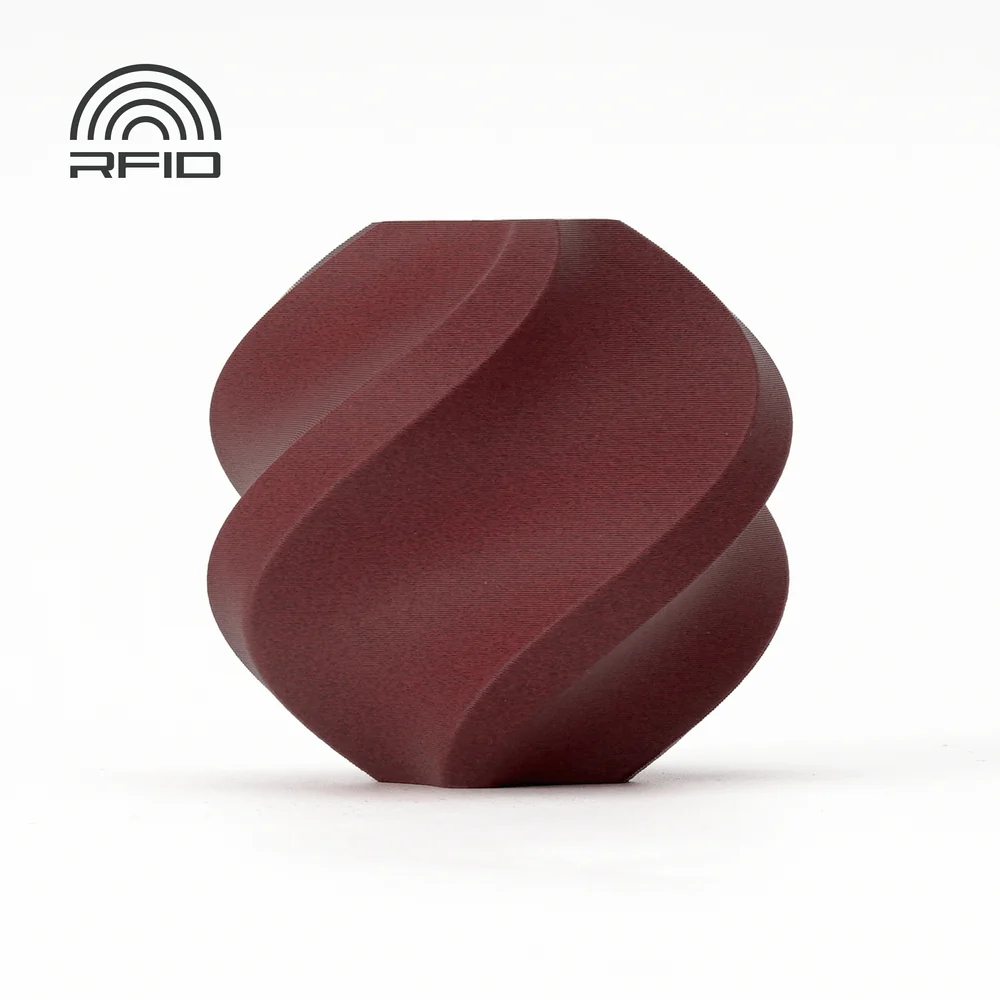

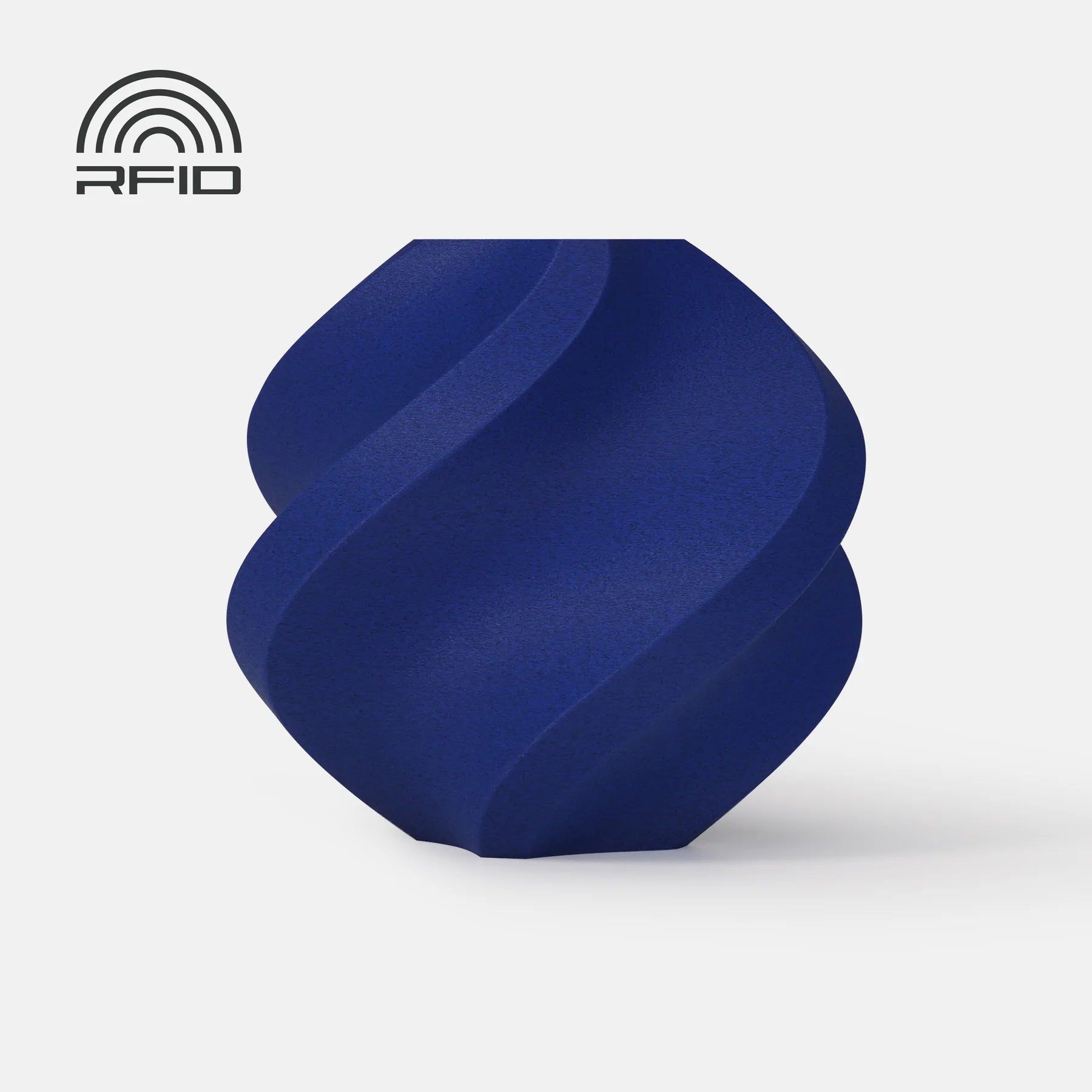

Carbon fiber texture & Minimized layer lines

The addition of carbon fiber gives prints a unique matte finish and effectively hides layer lines, providing a smooth, premium look.

Improved mechanical properties

Bambu PLA-CF exceeds the mechanical properties of PLA Matte in XY Bending Strength, Z Bending Strength, XY Bending Modulus, Z Bending Modulus, XY Impact Strength, and Z Impact Strength by between 20% and 115%, making it more suitable for printing models with higher strength requirements.

Stabilized printing dimension

Bambu PLA-CF features low shrinkage and warping resistance to achieve perfect matching accuracy between printed parts.

Minimal effort in support removal

Bambu PLA-CF is designed to support itself. It can be removed more easily compared to regular PLA, and still maintains a smooth support surface.

Not prone to clogging in high-speed printing

Bambu PLA-CF is just as easy to print as regular PLA. It can be printed smoothly and consistently at high speed without clogging.

Product Features

- Carbon Fiber Texture & Minimized Layer Lines

- Improved Mechanical Properties

- Stablized Printing Dimension

- Comes with Basic Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use

- 0.2 mm Nozzle Not Compatible

- Stainless Steel Nozzle Not Recommended

- Dry before Use for the Highest Print Quality

- AMS Compatible

Recommended Printing Settings

| Drying Settings (Blast Drying Oven) | 55 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 210 - 240 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 200 mm/s |

Physical Properties

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | 69 °C |

| Heat Deflection Temperature | 55 °C |

| Melting Temperature | 165 °C |

| Melt Index | 3.7 ± 0.6 g/10 min |

Mechanical Properties

| Tensile Strength | 38 ± 4 MPa |

| Breaking Elongation Rate | 8.4 ± 3.2 % |

| Bending Modulus | 3950 ± 190 MPa |

| Bending Strength | 89 ± 4 MPa |

| Impact Strength | 23.2 ± 3.7 kJ/m² |

Printing Tips

• Drying conditions: 55℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI.