Bambu Lab PETG-CF

Bambu PETG-CF

Bambu PETG-CF is a composite material consisting of PETG and carbon fiber. The new formula greatly improved printing quality by reducing clumping compared to traditional PETG. With the addition of carbon fiber, Bambu PETG-CF offers improved strength while maintaining good toughness and a shiny look. It is an ideal material for drone parts, racing models, and various functional parts that require both high performance, especially impact strength, and a sleek appearance.

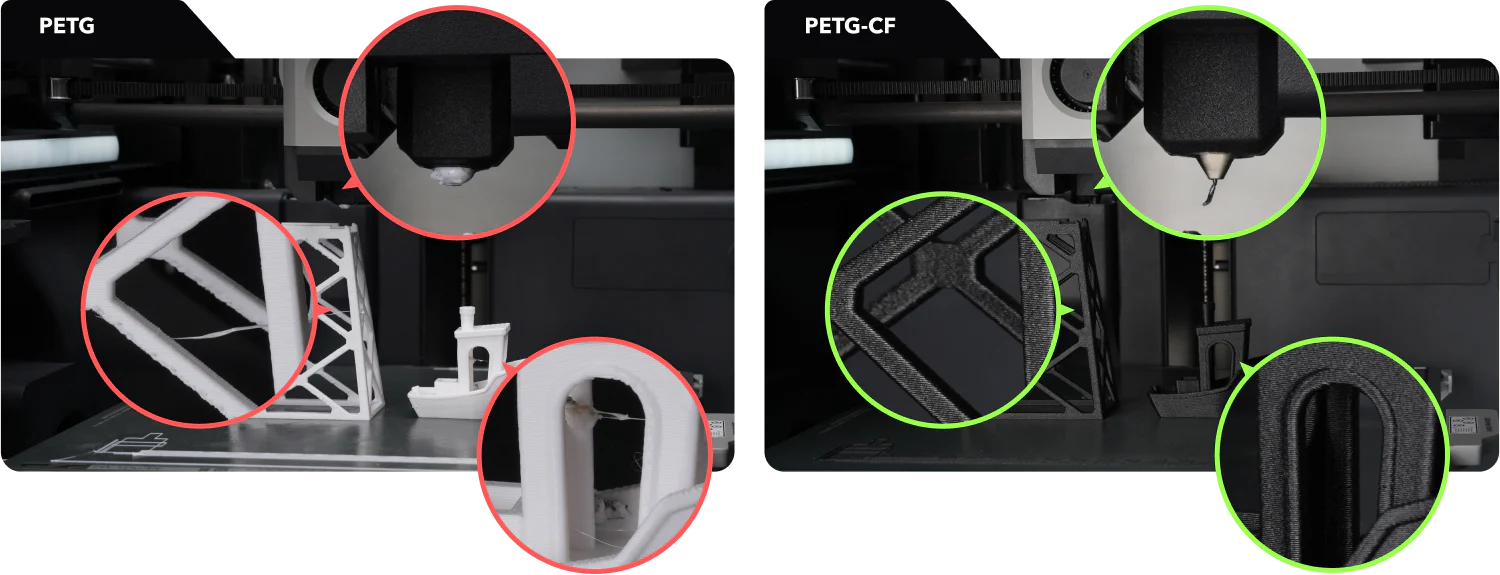

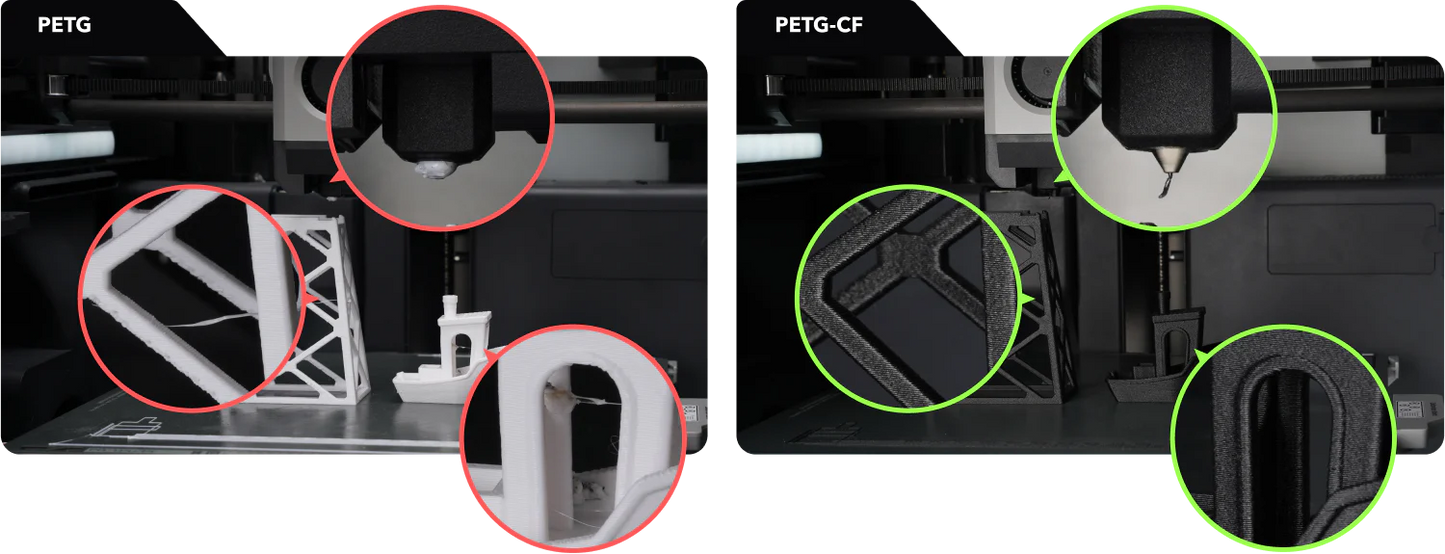

Less clumping and stringing

Bambu PETG-CF is improved with a modified formula that specifically addresses the issue of clumping and sticking to nozzle during PETG printing.

Premium print surface

Carbon fiber brings advanced texture to the print surface, while retaining the shine of PETG itself.

Carbon Fiber Texture

Carbon fiber brings soft reflection, minimal layer lines and a unique delicate texture.

Shiny Finish

Different from PLA-CF's matte finish, PETG-CF offers a shiny finish and thus one more choice.

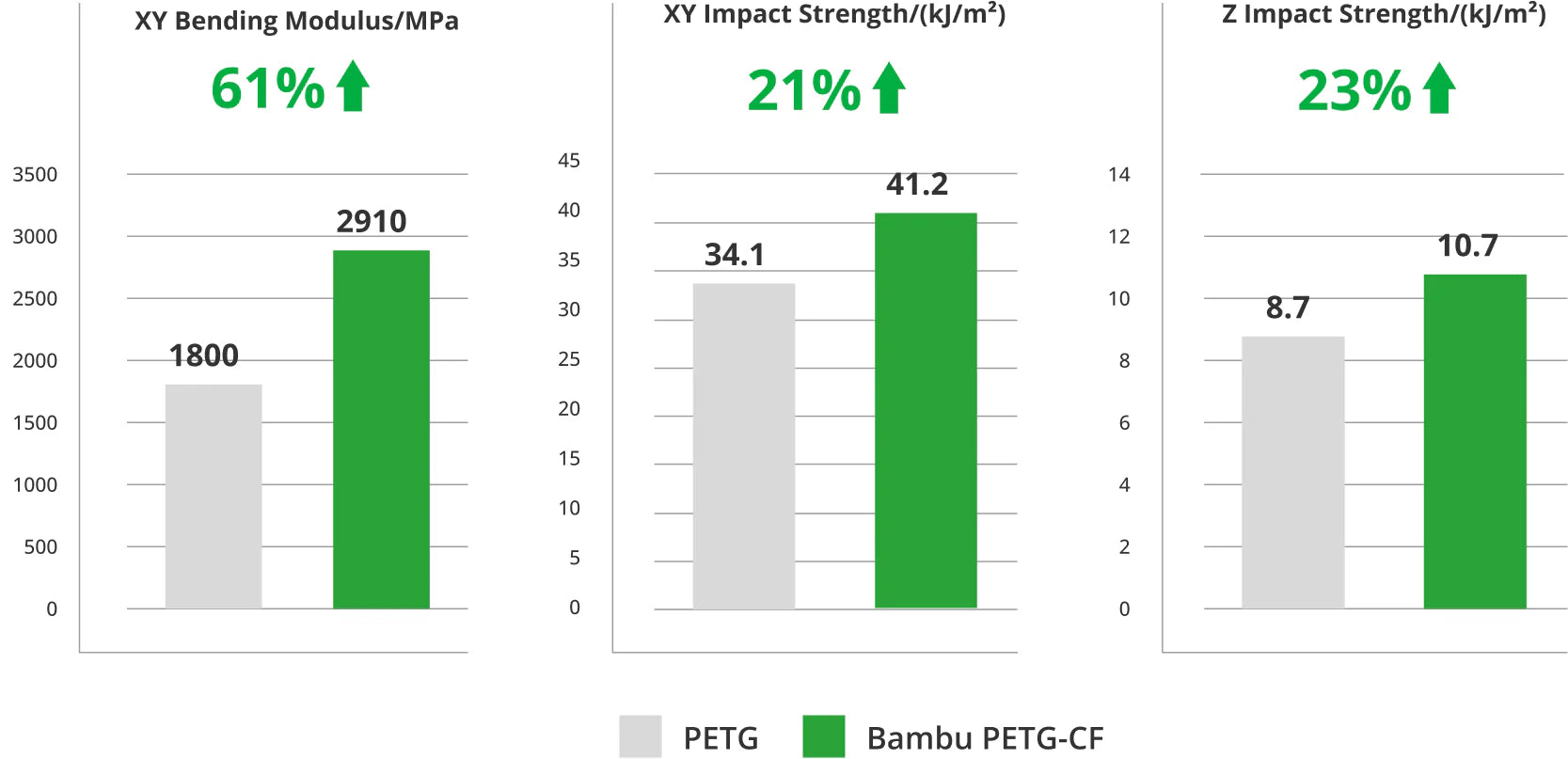

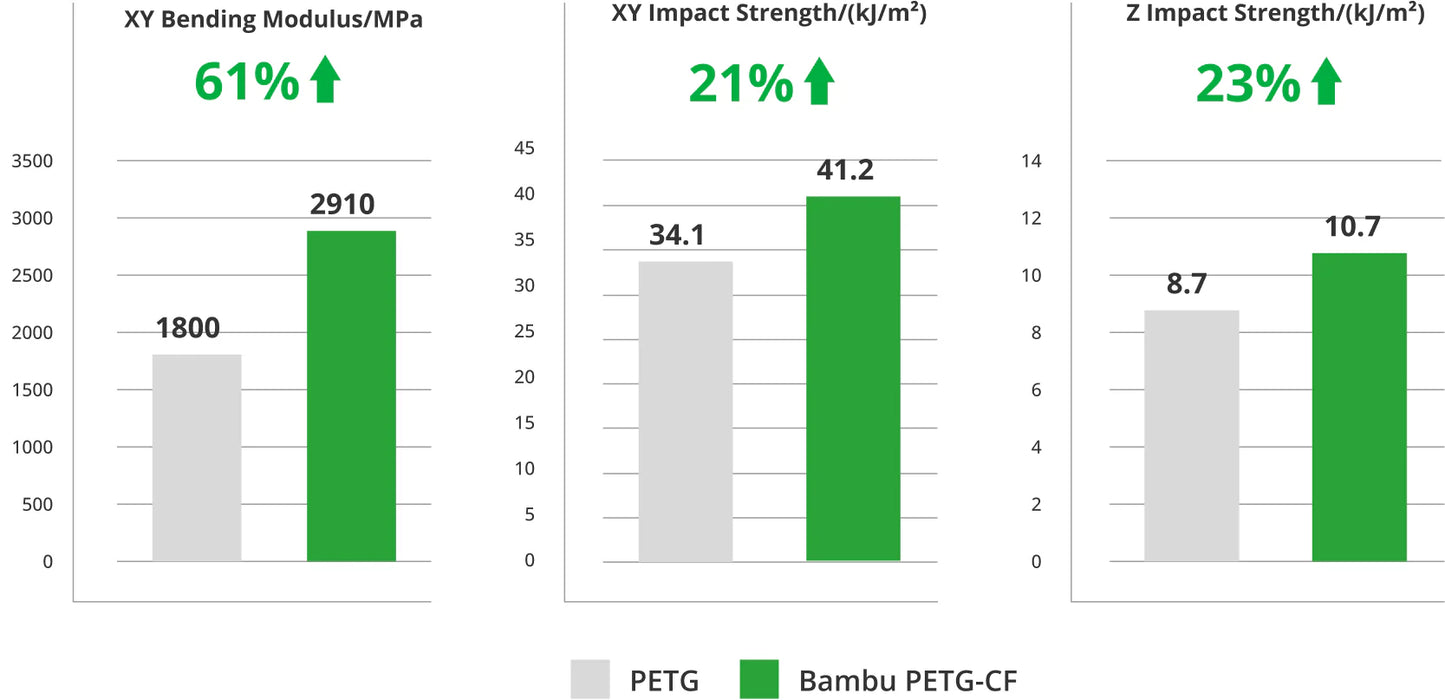

Strong XY Performance

The addition of carbon fiber also significantly enhances the XY strength of PETG without sacrificing layer bonding.

High Flexibility

Compared to other carbon fiber materials, Bambu PETG-CF exhibits exceptional toughness

and is less prone to fracture under external stress and impact.

Product Features

- Less Clumping and Stringing

- Premium Print Surface

- Improved Mechanical Properties & High Flexibility

- Comes with Basic Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use

- 0.2 mm Nozzle Not Compatible

- Stainless Steel Nozzle Not Recommended

- Dry before Use for the Highest Print Quality

- AMS Compatible

- AMS lite NOT Compatible

Recommended Printing Settings

| Drying Settings (Blast Drying Oven) | 65 °C,8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 240 - 270 °C |

| Bed Temperature (with Glue) | 65 - 75 °C |

| Printing Speed | < 200 mm/s |

Physical Properties

| Physical Properties | |

| Density | 1.25 g/cm³ |

| Vicat Softening Temperature | 85 °C |

| Heat Deflection Temperature | 74 °C |

| Melting Temperature | 225 °C |

| Melt Index | 19.3 ± 2.4 g/10 min |

Mechanical Properties

| Mechanical Properties | |

| Tensile Strength | 35 ± 5 MPa |

| Breaking Elongation Rate | 10.4 ± 0.6 % |

| Bending Modulus | 2910 ± 260 MPa |

| Bending Strength | 70 ± 5 MPa |

| Impact Strength | 41.2 ± 2.6 kJ/m² |

Printing Tips

• Bambu PETG-CF needs proper drying before printing. Drying conditions: 65 ℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details please refer to: Filament drying instructions on WIKI.

• To get stronger Z-adhesion, please set a higher infill density, and do not use an open-frame printer or set too large fan percentages to avoid over cooling.

• To get shinier looks, set lower speeds and relatively higher temperatures.