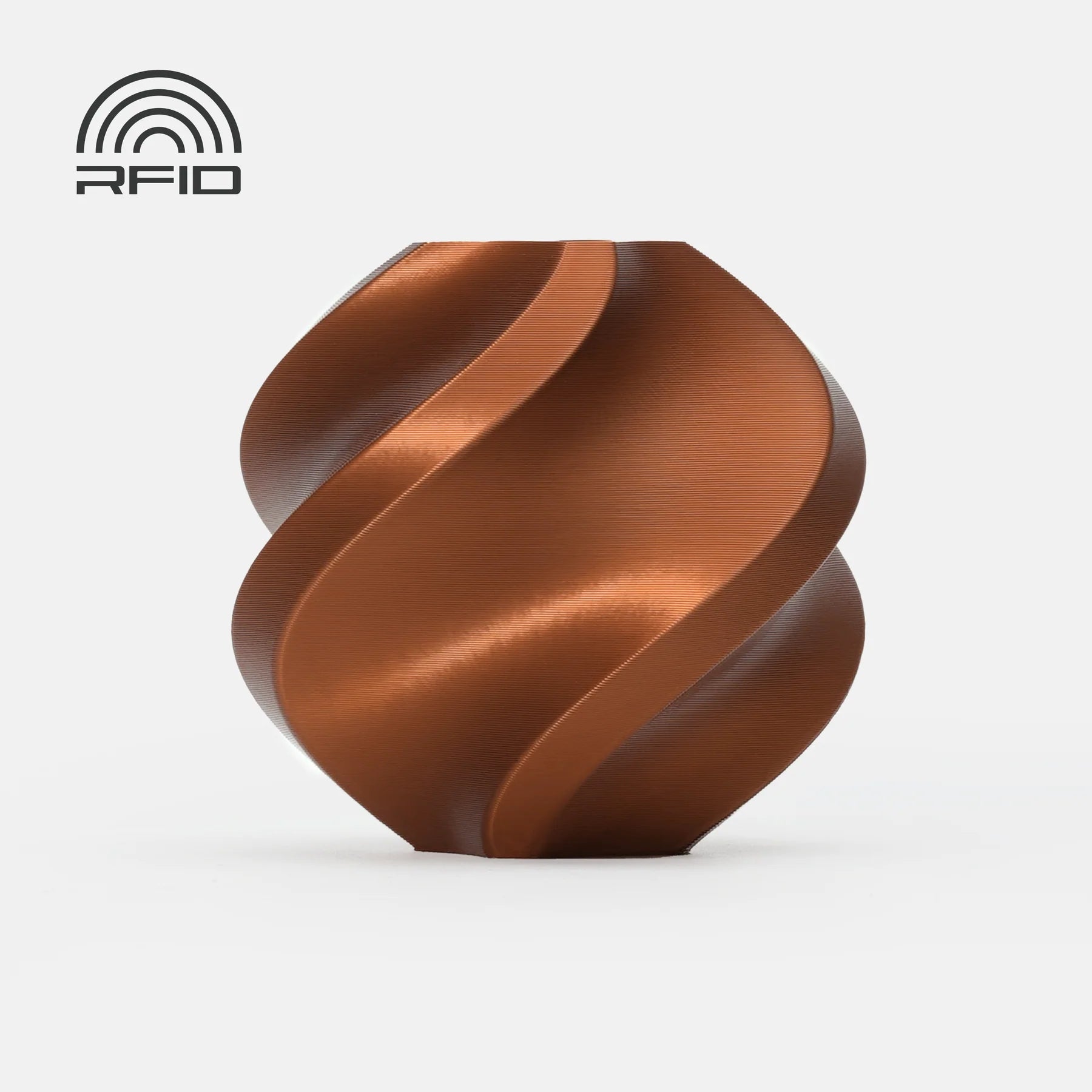

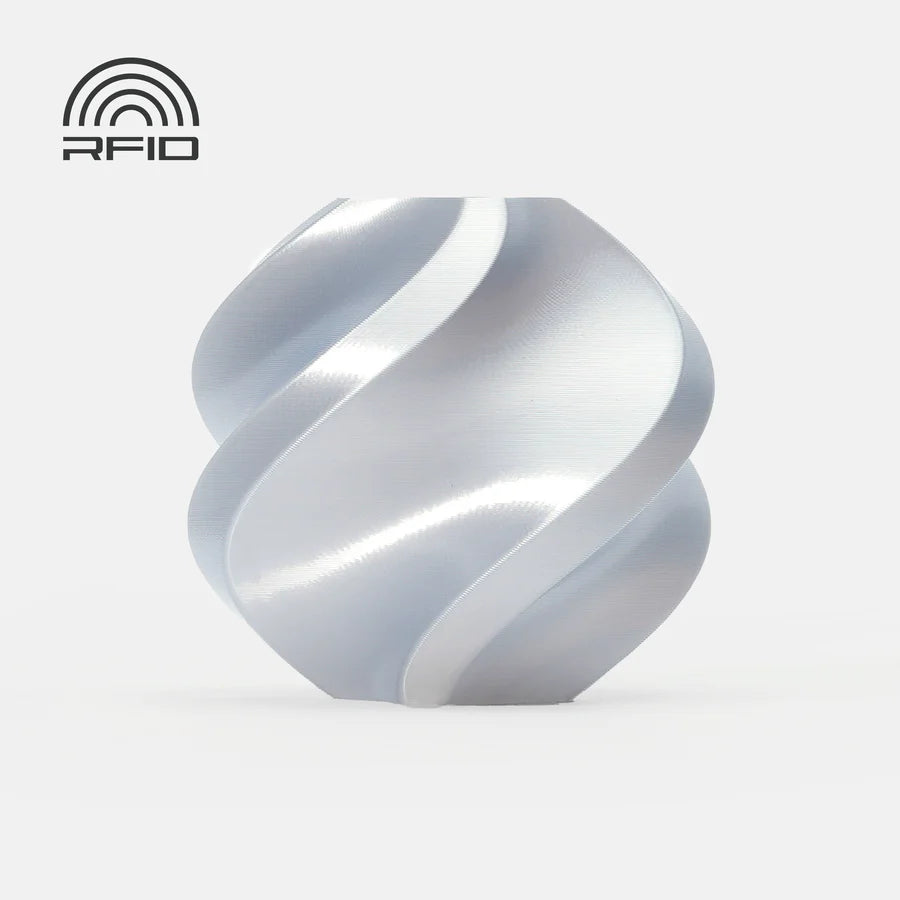

Bambu Lab PLA Silk

Bambu PLA Silk offers a silk-like and high-glossy that adds a luxurious appearance to your prints while retaining PLA's ease of use. Unlike other silk filaments, Bambu PLA Silk was engineered to be tougher and demonstrate greater resistance to breakage while using the AMS. It is ideal for decorations, artistic projects, and 3D character models, or any parts where you are looking for a silk-like finish.

Product Features

- Silk finish with dynamic color transformations

- Controllable gloss finish

- Comes with basic reusable spool

- Diameter: 1.75 mm

Cautions for Use

- AMS Compatible

Recommended Printing Settings

| Drying Settings (Blast Drying Oven) | 55 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 210 - 230 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 250 mm/s |

Physical Properties

| Density | 1.32 g/cm³ |

| Vicat Softening Temperature | 56 °C |

| Heat Deflection Temperature | 53 °C |

| Melting Temperature | 152 °C |

| Melt Index | 20.5 ± 1.2 g/10 min |

Mechanical Properties

| Tensile Strength | 27 ± 4 MPa |

| Breaking Elongation Rate | 3.5 ± 0.6 % |

| Bending Modulus | 2370 ± 150 MPa |

| Bending Strength | 66 ± 4 MPa |

| Impact Strength | 24.5 ± 1.7 kJ/m² |

Printing Tips

- The level of gloss of printed parts with PLA Silk can be controlled by printing temperature and speed. For higher gloss finishes, increase the temperature and/or decrease the speed.

- Recommended settings for glossy finish: Nozzle temperature: 230 - 240 °C, Outer wall speed: 30 - 60 mm/s

- Drying conditions: 55℃ for 8 hrs. Store in a dry environment after use. Dry before use if the material absorbs moisture. For more details, please refer to: Filament drying instructions on WIKI.